November 14, 2005

Mike "The Man" fixed my ghetto spacers.

It is much easier to make a circle with cnc than manual, however I still think II got pretty close.

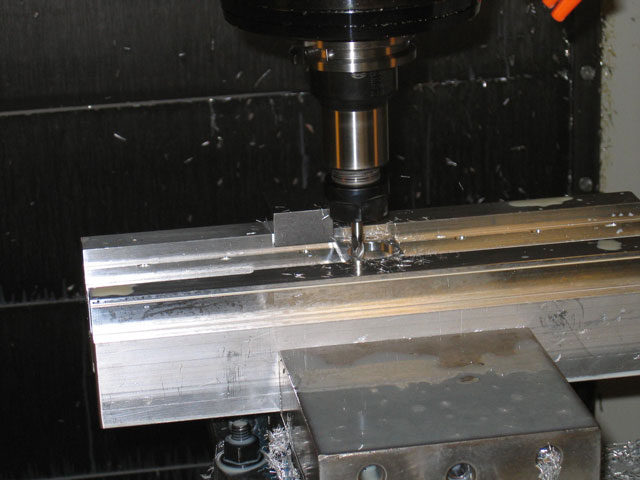

Oh yeah, that's what I'm talk'n bout, 5 axis to cut a hole.

Yeah, looks much better, thanks Mike.

While riveting the emp. I often wondered what an acceptable tolerance was for the shop head. I would run my rivet go/no-go gage (sheet metal with a .140 hole) over the shop head and if it didn't fit or fit snug I would call it good, but if it fit with little room I wasn't sure what to do. If it was .130 should I smash some more? Here I tested 2 samples at a shop head dia.of .128 in., 2 at .140, and 2 at .150 just to compare with one another, I understand these samples sizes are not statistically significant. I would do more if I had time. These rivets are AN426AD3-3.5 in approx. 1in. strips with dimples.

sample in machine

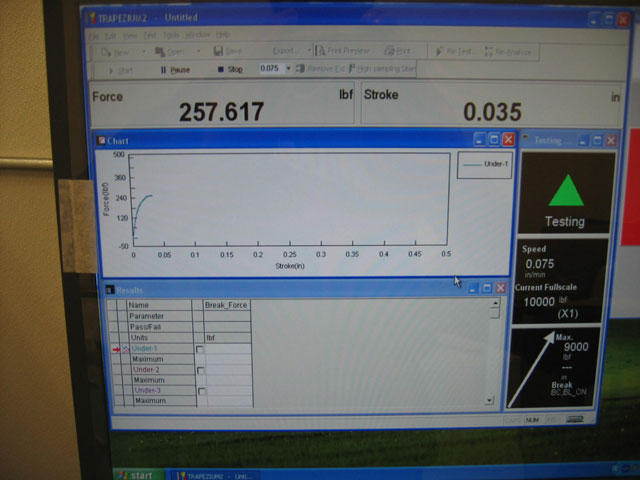

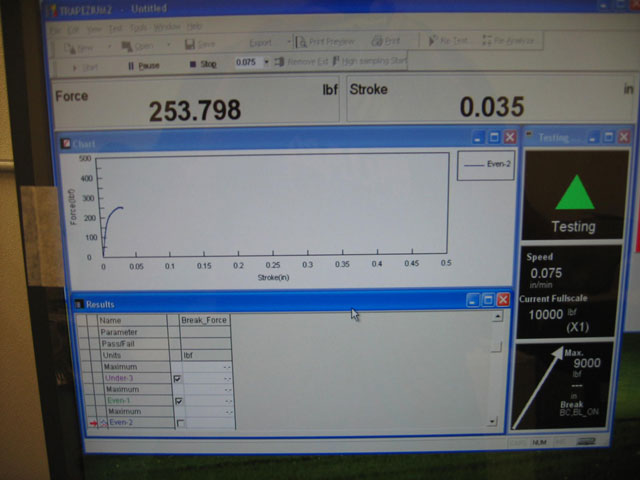

1st .128 sample. I snapped a picture as close as I could to thee peak force. I have the raw data, will post when I can.

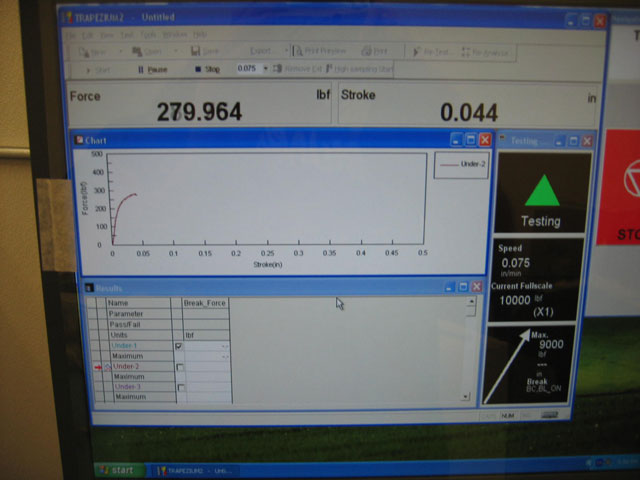

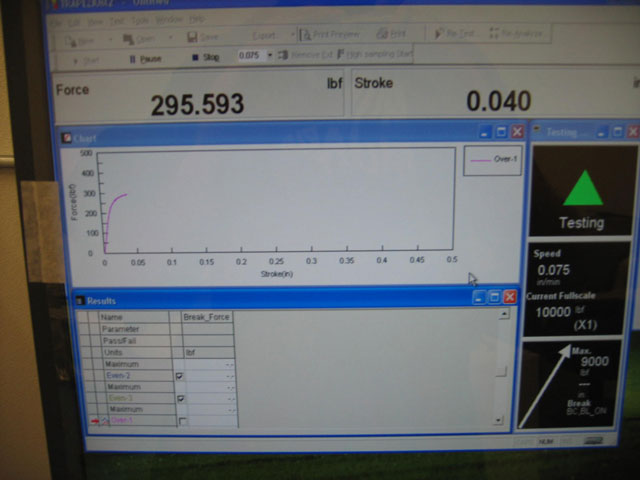

2nd .128 sample

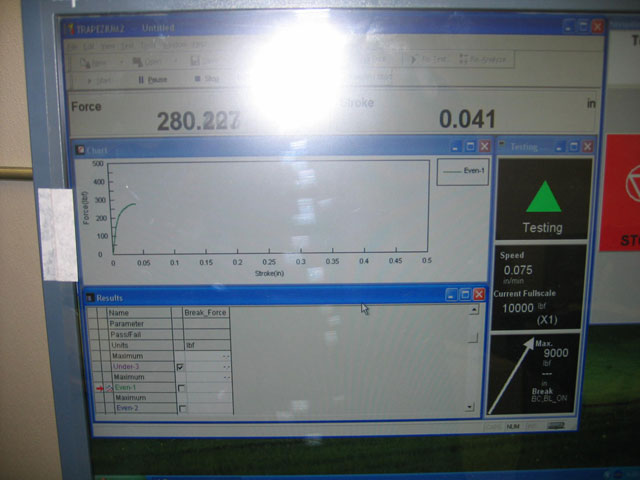

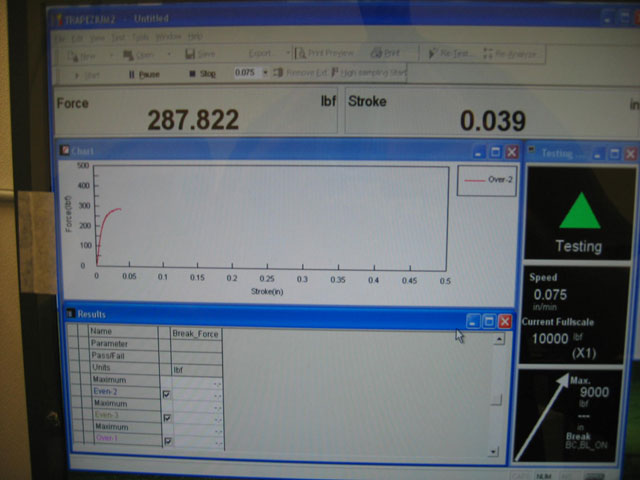

1st .140 sample

2nd .140 sample, this one was weird, low value for a nominal sample.

1st .150 sample

2nd .150 sample

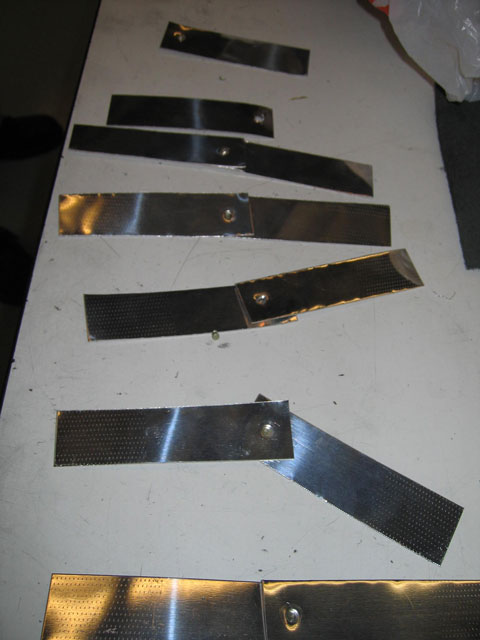

All failure seemed to look the same.

Kind of like this.

Here are the tested samples. Conclusion, well just like I've heard already, error on the big side.